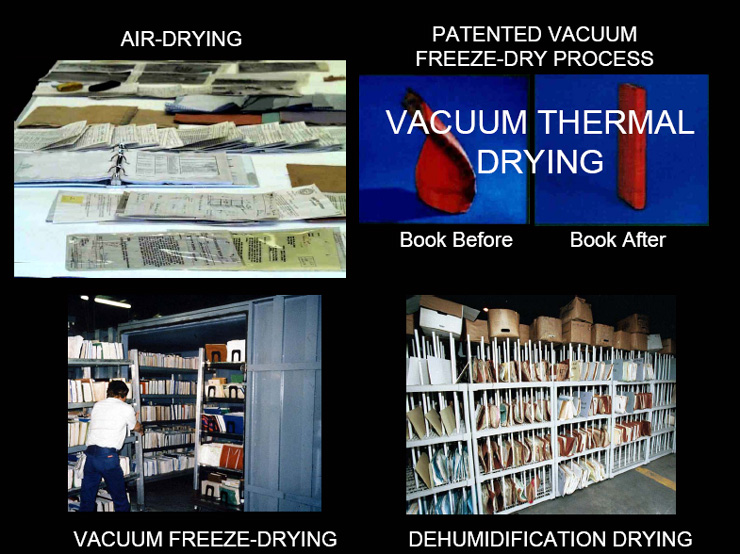

Comparison of Drying Methods

In Air Drying, records dry at room temperature in-house. Materials are typically dried in a prepared workspace-- spread out on, or interleaved with, absorbent papers. In some instances, items may be dried under restraint in a stack of weighted blotters.

Dehumidification-drying, is also referred to as desiccant-drying. Here, dehumidified air is introduced at very low relative humidities, often below 15% to a drying space. Air temperatures vary throughout the drying process, but are usually in the range of 26-37oC. (72-100oF)

Vacuum freeze-drying is generally recommended for large quantities of wet or damp materials. Items must be frozen prior to entering the vacuum freeze-drying chamber where they are exposed to a high vacuum at temperatures below freezing. Cycles of controlled heat are applied while materials remain frozen throughout the drying process. Frozen water sublimates to a vapor without passing through a liquid stage--an advantage in minimizing feathering and bleeding of soluble media. Coated materials dry without blocking, and minimal distortion results. Mobile vacuum chambers can be brought on-site, or items can be sent to a drying facility. Drying time depends on wetness of materials, but can usually be accomplished within two weeks.

The fourth method we set out to investigate was vacuum thermal drying, recommended for wet or damp materials. Items are placed into a chamber wet or frozen, and dried under a vacuum with air above freezing temperatures. Vacuum thermal drying is cited as a less costly option for un-coated papers of low intrinsic value. This procedure causes coated records to block, distorts paper, and promotes the feathering and bleeding of soluble inks. Drying time is usually shorter than vacuum freeze-drying, but this will depend on initial wetness.

We did not, in fact, investigate vacuum thermal drying as described, though this was the service we intended to purchase. A misunderstanding of terminology resulted in thermal vacuum freeze-drying rather than vacuum-thermal drying. This only became obvious once materials were returned and did not display the characteristic effects anticipated--such as blocking of coated paper, and feathering and bleeding of soluble inks.

Results from this patented thermal vacuum freeze-drying process did offer a useful comparison with other methods evaluated. Thermal vacuum freeze-drying is similar to vacuum freeze-drying, but employs a patented procedure to compress subjected materials into shape. Such patented processes may not be universally available, and like other technologies, may be specific to particular locales.